Construction machinery

Agricultural machinery

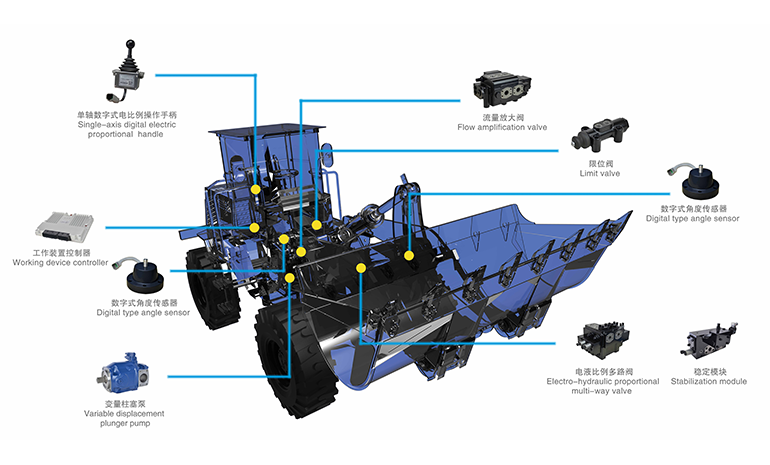

The complete variable load-sensitive electro-hydraulic proportional system for 3-9 ton loaders is composed of variable displacement axial piston pump, electro-hydraulic proportional multi-way valve, flow amplification valve, high-performance controller, electro-proportional control handle, high-precision sensors, etc.

4 displacement size of SA10VO variable pumps are available: 71/85/100/108 mL/r.

It provides valve-after-pressure-compensated load-sensitive valves with both hydraulic and electro-proportional control modes, with a flow range of 250~450 L/min. The valves are equipped with built-in hydraulic locks to prevent cylinder sinking for the boom and bucket. They feature a backpressure valve in the return oil path to ensure that the rod-side chamber of the cylinder does not draw in air and provide efficient energy-saving operation.

Five major control functions: End position and arbitrary position buffering, automatic bucket leveling, parallel movement and lifting, micro-movement of the boom and bucket, and automatic positioning of the boom and bucket.

Pressure and angle sensors are combined with optimized algorithms for automatic weighing.

It comes with a human-machine interface that includes features such as work device status display, fault record inquiry and diagnosis, parameter settings, etc.

The CAN bus communication system allows real-time reading of engine and transmission oil temperature data, enabling independent heat dissipation. It can also send various information as required, facilitating remote monitoring.